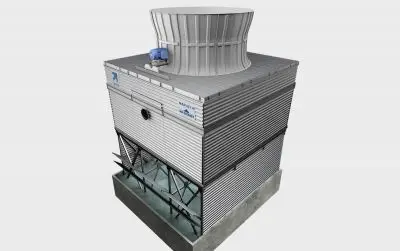

The Marley MD is a factory-assembled, counterflow cooling tower. For many HVAC and light industrial applications, this design requires less plan area and offers greater site placement flexibility than a comparable crossflow cooling tower. A broader box size selection and more design options have expanded the range of the versatile MD product line. New selections with anti-fouling film-type fill expand the MD’s applications to include process water with high solids content.

Back-to-back installation configurations for all models provide even more site placement adaptability. Optional mechanical access platforms are now available, whether factory assembled or field installed, that allow safe access to the mechanical system, water distribution system, fill and drift eliminators. The Marley MD is a CTI-certified, fully rated cooling tower for a wide range of flow and temperature requirements.

Unmatched Reliability

Heavy-duty construction, high-performance design, and our five-year mechanical warranty ensure consistent, fully rated cooling over a wide range of flow and temperature requirements.

Smaller Footprint

Induced-draft counterflow cooling tower design requires less plan area than crossflow cooling towers for many HVAC and light industrial duties. And because the cooling tower’s size typically results in less steel used, its reduced weight requires less support structure.

Low Energy Consumption

Induced-draft counterflow mechanical equipment minimizes the energy consumption by providing a lower fan energy requirement than centrifugal fan counterflow cooling towers.

Ease of Maintenance

SPX Cooling Technologies has worked hard to address the maintenance difficulties long associated with counterflow cooling towers. Our MD cooling tower provides larger access doors, easily removable block fill and other features that simplify maintenance.

Low Sound

The CTI-certified Marley MD cooling tower comes standard with our low-sound fan, suitable for most noise-sensitive situations. Multiple fan and attenuation options are available to meet more stringent sound requirements.

Independently Validated Sound Data

Marley towers are the only package cooling towers tested per CTI ATC-128 test code by third-party CTI-licensed test agents and certified acoustical engineers. MD sound levels are independently verified to meet published sound levels.

Superior Water Management

To address the “splash-out” problem typically found in other manufacturers’ counterflow cooling tower designs, SPX introduces an industry first: a triple-pass inlet louver that conserves water and improves winter operation.

FM Approval

For applications of two or more cells, the MD tower conforms to the FM Approval Standard for cooling towers, Class Number 4930.

Factory assembled or field erected, the Marley MCW steel forced draft counterflow cooling tower is an ideal solution for sound and space-sensitive applications.

Low Maintenance

Unlike most forced draft cooling towers, the Marley MCW cooling tower utilizes large access doors for easy entry and exit. In addition this configuration provides easy access to the motors and fans from grade.

Quiet by Design

All Marley MCW cooling towers are designed for low sound levels by utilizing centrifugal fans and a fully contained water splash zone. In addition, for those applications where sound is more of a concern than typical, consider air inlet or outlet attenuation for the ultimate in quiet cooling tower operation.

Long Life Construction

Rugged G235 heavy mill galvanized steel (G600 in Europe/Z600 China) is standard with S300 series stainless steel as an optional upgrade to part or the entire cooling tower structure. ISO certified plants assure quality factory-assembly

The Marley CP Cooling Tower is an induced-draft, counterflow tower uniquely designed for space- and sound-sensitive applications. It features a stainless steel internal structure and fiberglass reinforced polyester (FRP) casing to resist corrosion and chemical attack.

A range of heat transfer fill media accommodates clean-to-very dirty water applications. The Marley CP Cooling Tower can be fully factory assembled, partially assembled, or shipped fully knock-down for on-site assembly.

CTI and Eurovent Certified

The thermal performance of the Marley CP Cooling Tower is tested and certified by the Cooling Technology Institute (CTI) and Eurovent.

Mode of Operation

Hot water flows into the cooling tower through PVC (polyvinyl chloride) or polypropylene piping to the water distribution system. Spray nozzles uniformly distribute fine droplets of hot water from above the heat transfer fill. The cooling air is provided by an induced-draft axial fan. Air absorbs the heat from the water by evaporation and convection.

Heat Transfer Fill Media

Clean water applications utilize PVC or polypropylene film fill packs. Dirty water containing higher suspended solids content requires clog-resistant or splash fill.

Mechanical Equipment

The fan is mounted directly on the geared motor shaft. Fan blade pitch is adjustable to process conditions. The low-noise cooling tower duty motor is engineered to withstand high heat and moisture conditions and suitable for continuous operation with a variable frequency drive (VFD). Motor and fan are mounted on a hot dip galvanized (HDG) steel (or optional stainless steel) support structure.

Multiple Cells Configuration

Multi-cell CP Cooling Towers can be installed inline or back-to-back.

Counterflow cooling tower design allows maximum thermal performance capability per unit of plan area. Minimizes pump head requirements. Available with your choice of heat exchange media to satisfy just about any water quality. In addition, fiberglass, concrete or wood structure give you the flexibility to choose the material best for your cooling tower application.

Fiberglass Pultrusion Counterflow Cooling Towers

Pultruded structural components used throughout the cooling tower produce an engineered framework of unsurpassed quality, reliability and safety. Structural pultrusions approximate the strength of steel in tension and compression. Fiberglass is impervious to a broad range of corrosive materials—immune to deterioration.

Concrete Counterflow Cooling Towers

800 class concrete cooling towers are hurricane and typhoon resistant by virtue of mass, and concrete defies the detrimental effects of heat and ultraviolet light. Concrete is a natural material which is ideally suited for long service life in the harshest cooling tower environment. And concrete will never degrade the quality of cooling water circulating through the tower Available in precast concrete for jobs where schedule and economics favor an ‘assembled” product, or cast-in-place when in situ forming and casting are favored. Cellular or multi-fan cooling tower configurations available to suit site requirements.

Wood Counterflow Cooling Towers

All cooling tower wood is pressure treated after fabrication. All fabricated steel components are hot dip galvanized or stainless steel. Extensive use of inert plastics for structural and non structural components. Designed for heavy industrial use with long service life.

Each tower is individually designed for the investment and installation requirements. The use of Marley components responsible for the exchange of heat to guarantee the desired performance.

Tailored to water quality for maximum lifetime performance. High temperature resistance design fill & water distribution system tailored for specific system solutions.

Ideal for highly chemically contaminated water or at high salinity, e.g. with seawater as cooling medium.